Sorting & Recycling Solutions

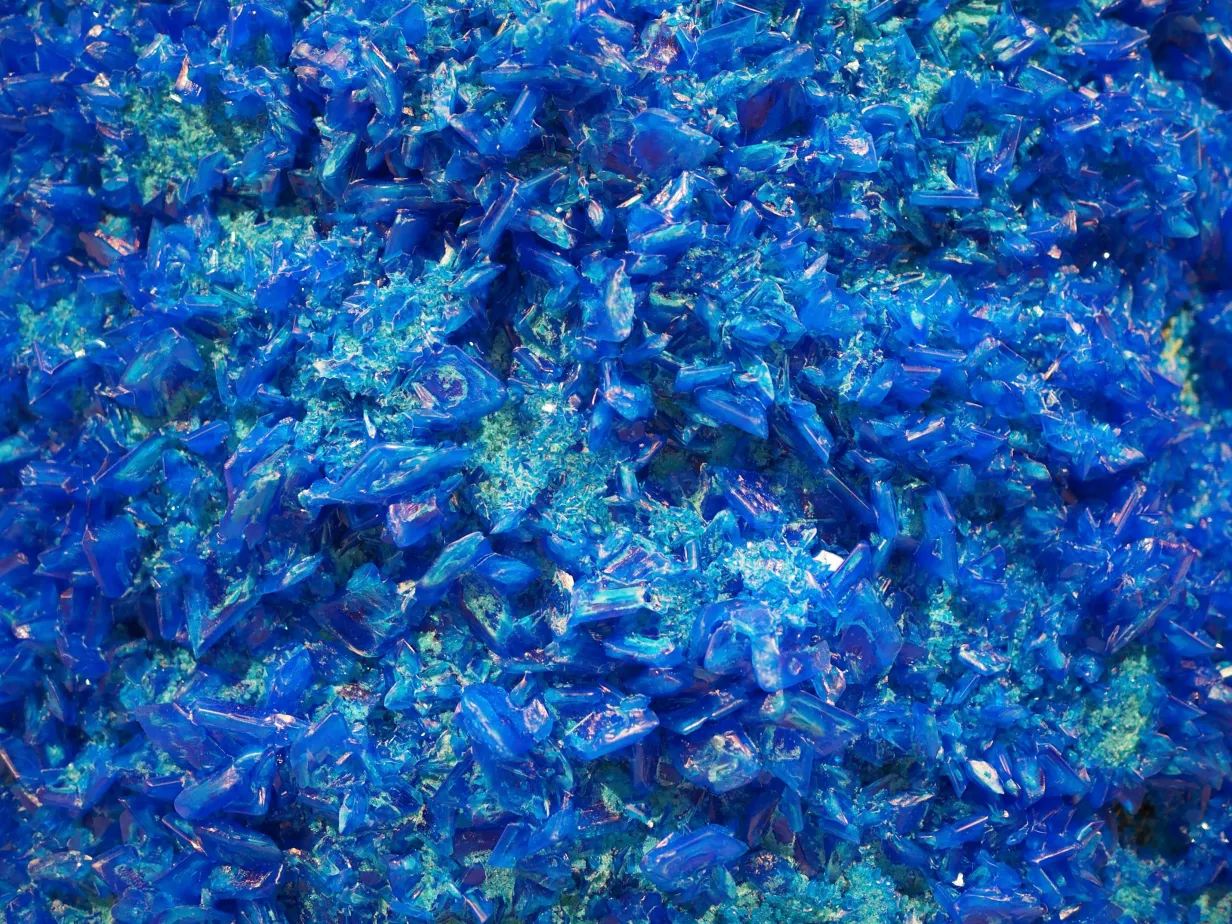

Optimize your recycling facility operations with advanced AI vision systems.

Monitor material quality, reduce contamination, and increase throughput in real-time with our flexible camera solutions.

Advanced Camera Systems

Automated waste analysis

No more manual audits, no installation costs, full data transparency. Our AI camera systems provide constant, accurate insights into your material streams.

Traditional quality control in recycling facilities relies heavily on manual inspection, which is labor-intensive, inconsistent, and limited by human capabilities.

Our AI camera systems can be deployed in fixed installations, mobile units, or semi-mobile setups, giving you complete flexibility to match your facility's needs and budget.

Each system provides real-time material detection, contamination alerts, and comprehensive analytics through our cloud dashboard.

Whether you're monitoring a conveyor belt, inspecting bales, or analyzing a specific process point, our systems provide consistent, objective data when needed.

Camera System Options

Operational Benefits

Zero Downtime, No Installation Costs

No need for costly setup or facility downtime. Our AI tools integrate seamlessly into your existing processes, enabling continuous, real-time quality control with no disruptions.

Optimize Sorter Settings with Real-Time Data

Adjust sorter settings based on accurate, real-time material composition data—improving sorting efficiency without the need for manual recalibration or guesswork.

Proactively Address Process Issues

Identify and resolve potential process inefficiencies or material quality issues before they cause costly downtime or delays in production.

Efficient Reporting for Compliance & Customers

Automatically generate detailed, data-backed quality reports for compliance, customer transparency, and performance tracking—saving time on manual documentation.

Reduce Manual Sampling & Testing Costs

Minimize reliance on manual sampling and laboratory tests with automated, on-site AI inspections that provide real-time material analysis, cutting costs and increasing efficiency.

Flow Optimization & Simulation

Visualize and Understand Material Movement

Our portable AI tools allow you to move flexibly throughout the facility, capturing data from various points in your process. This helps build a clearer picture of how different material streams behave and where inefficiencies or contamination might be occurring.

By linking localized inspections to specific areas in your facility, you gain valuable insights into material quality, operational flow, and potential improvement areas—without disrupting your processes.

While full simulation isn't available yet, our system already helps you trace material quality across key process stages, laying the groundwork for smarter decisions around equipment use, process adjustments, and resource allocation.

Platform Capabilities

Financial Benefits

No Upfront Installation Costs

Avoid the high capital expenditure of fixed inspection systems. Our mobile AI tools offer a cost-efficient alternative with no installation downtime or infrastructure changes required.

Lower Operational Costs

Reduce reliance on manual sampling, lab testing, and repeat inspections. AI-powered analysis streamlines workflows and cuts labor costs across multiple inspection points.

Faster ROI Through Flexibility

Use one system across different facilities or inspection areas. The portability and adaptability of our solution maximize utilization and accelerate return on investment.

Optimize Resource Allocation

With real-time quality data, focus resources where they're needed most—reducing waste, improving processing efficiency, and avoiding unnecessary costs.

Data-Driven Supplier and Pricing Strategies

Use consistent, objective data to support supplier negotiations, chargebacks, and dynamic pricing based on actual material quality.

Scalable Across Operations

Start small and scale as needed—our solution grows with your needs, making it financially accessible for both small facilities and large networks.